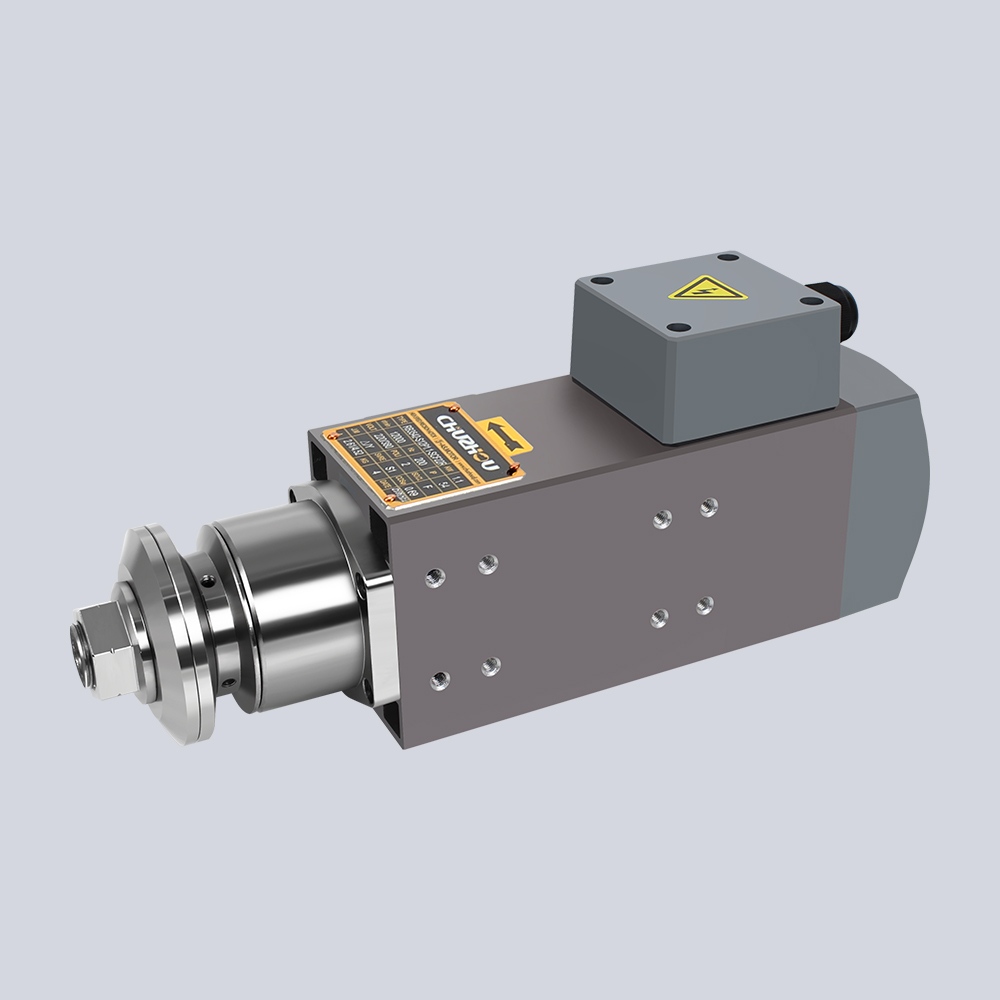

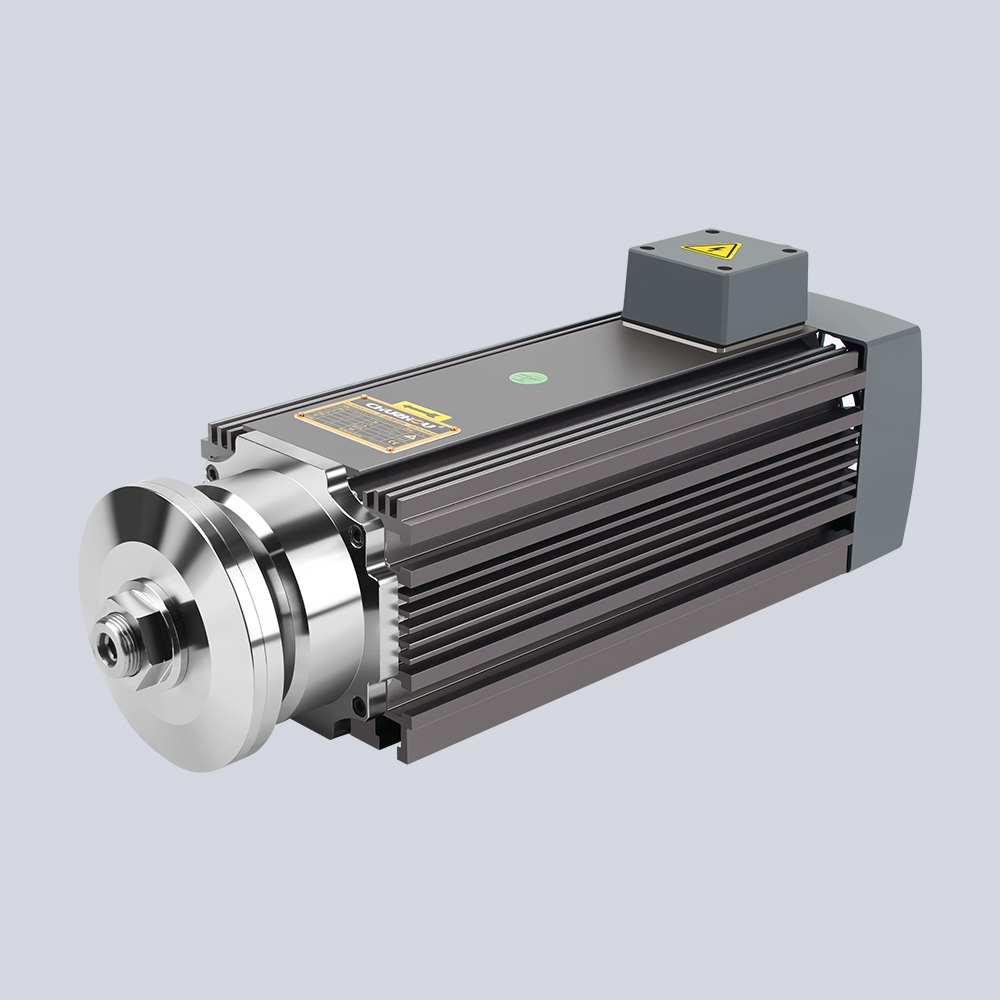

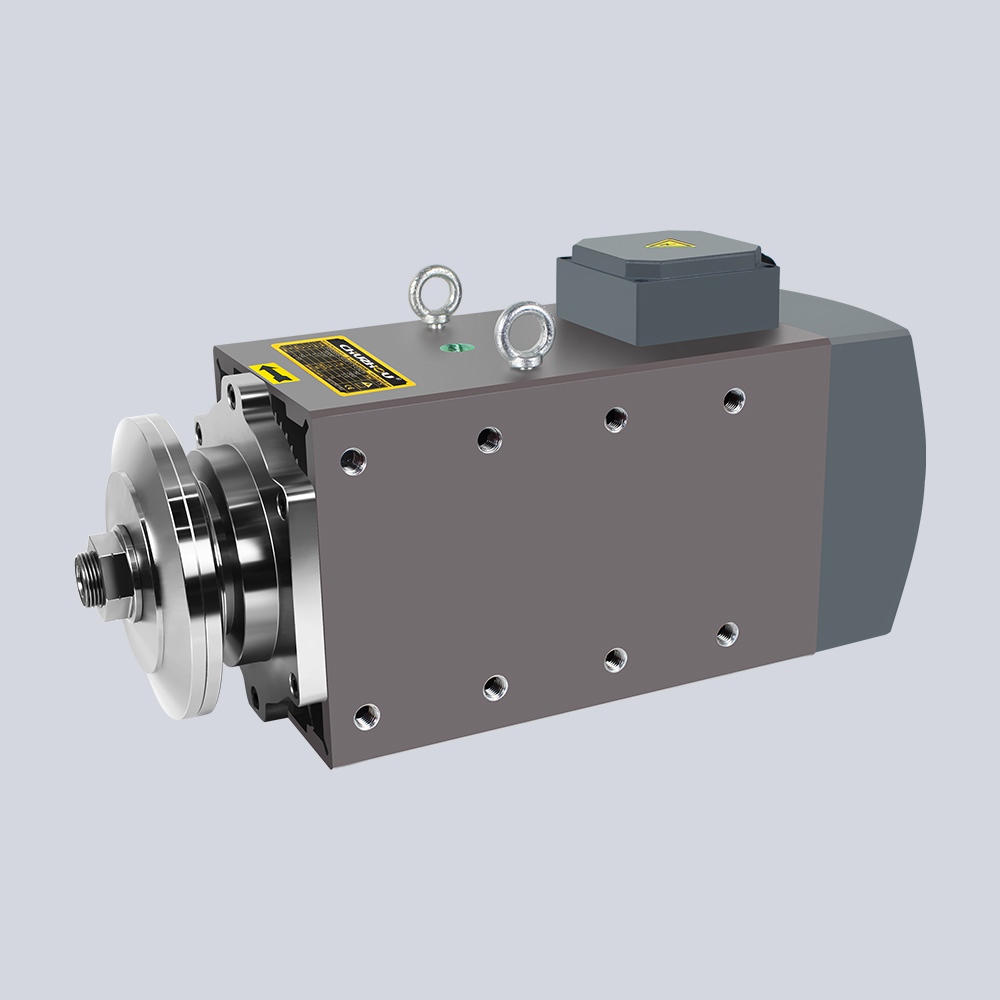

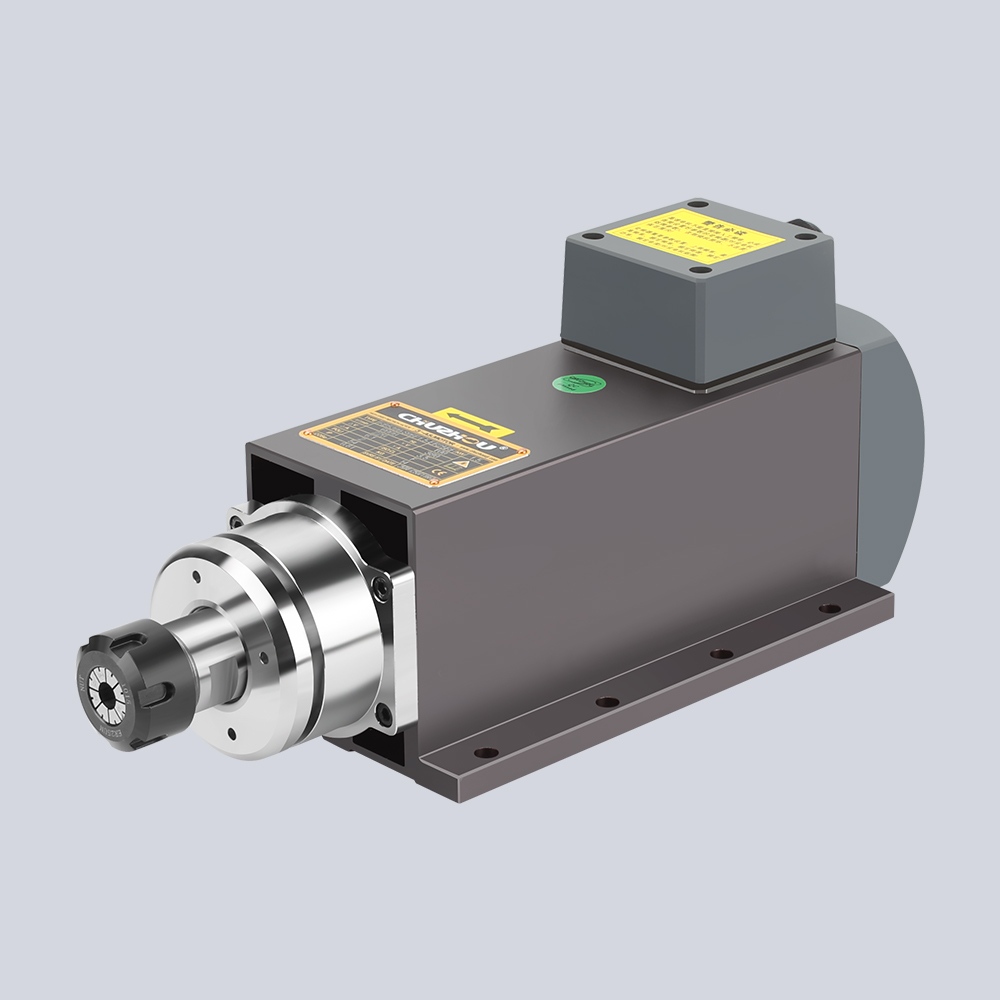

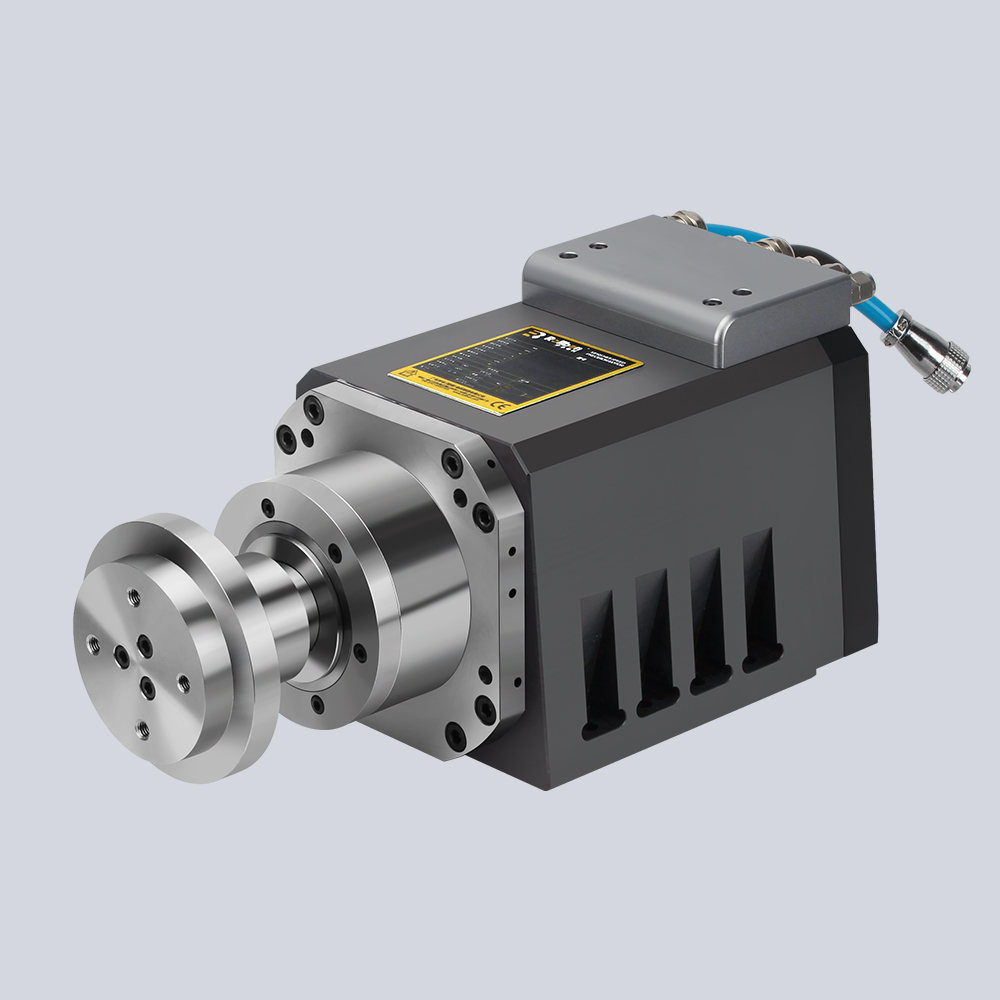

High-Speed Precision Spindle Motors in Modern Manufacturing

Modern manufacturing relies heavily on precision and efficiency, and high-speed precision spindle motors are at the forefront of this transformation. These motors, known for their high RPM and exceptional accuracy, are crucial in various manufacturing processes, offering solutions that drive productivity and quality.

Precision in Material Processing

High-speed precision spindle motors are integral to the processing of materials like aluminum, wood, plastic, and light alloys. Their ability to operate at high speeds with minimal vibration ensures that cuts are clean and precise, reducing material waste and improving the overall finish.Key Applications in Manufacturing

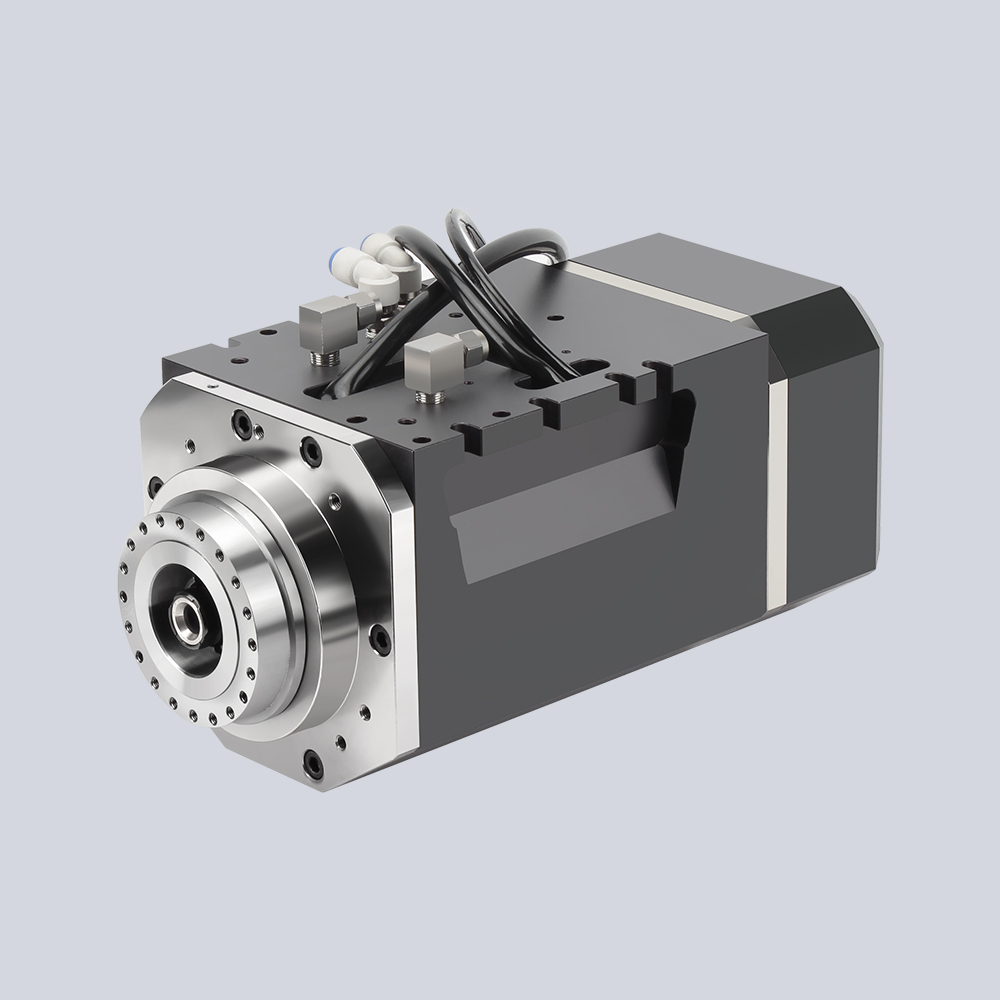

- Sawing and Cutting: In the manufacturing sector, the need for precise sawing and cutting cannot be overstated. High-speed spindle motors provide the power and accuracy required to cut through materials efficiently, making them ideal for producing components with exact dimensions.

- Grinding and Polishing: Surface finish is a critical factor in manufacturing. High-speed precision spindle motors excel in grinding and polishing applications, delivering smooth surfaces that meet stringent quality standards. Their high-speed operation allows for faster processing times without compromising on finish quality.

- Drilling and Carving: For manufacturers involved in detailed work, such as creating complex parts or artistic pieces, these motors offer the control and precision necessary to achieve detailed carvings and precise drilling operations.