Key Steps to Successful Installation of High-Speed Precision Spindle Motors

The installation of high-speed precision spindle motors is a pivotal process that influences their performance and longevity in manufacturing environments. This article provides a detailed roadmap for engineers and technicians, highlighting essential steps and considerations for achieving successful motor installation.

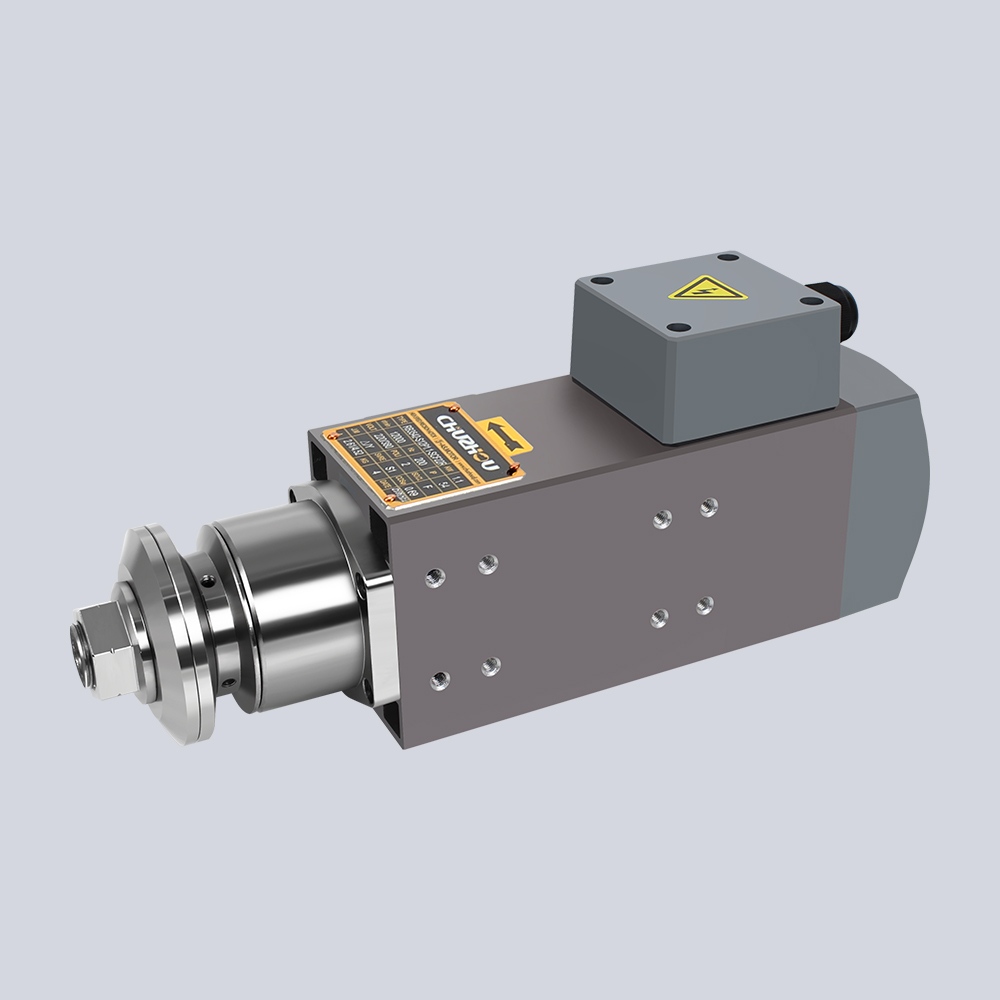

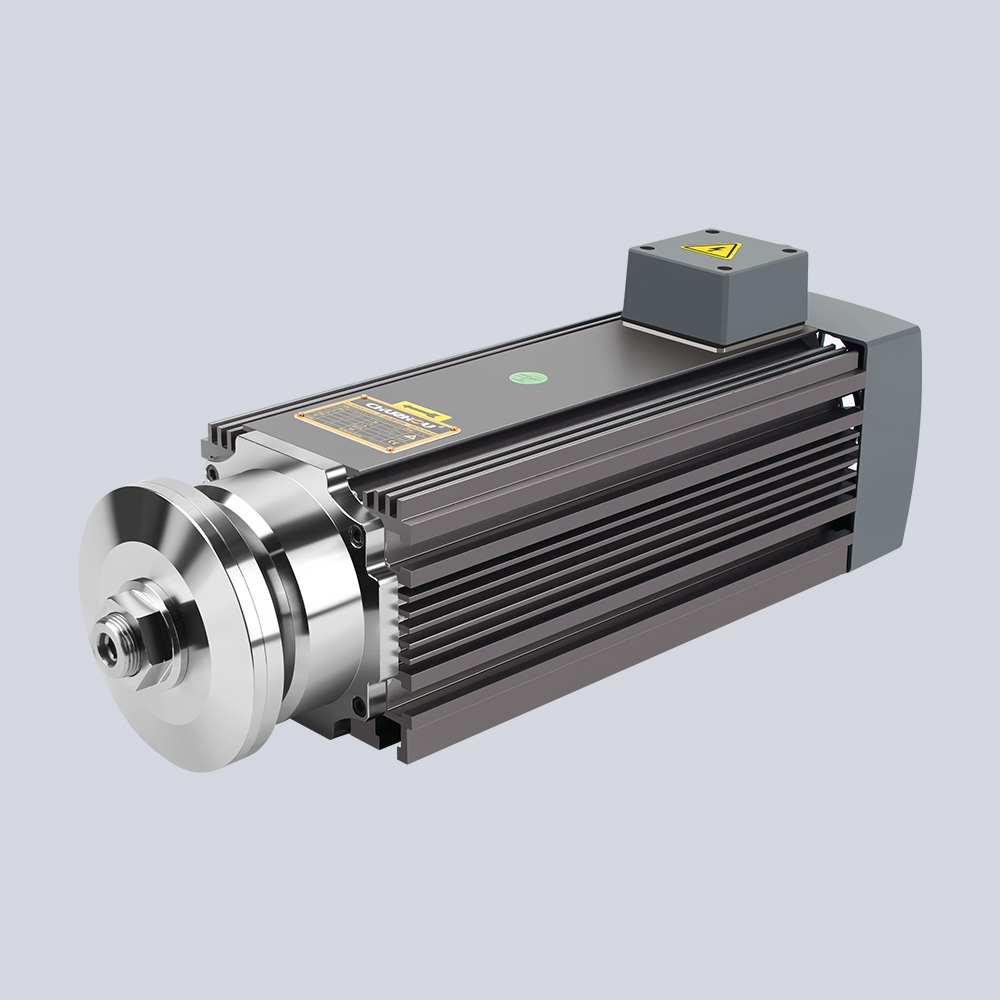

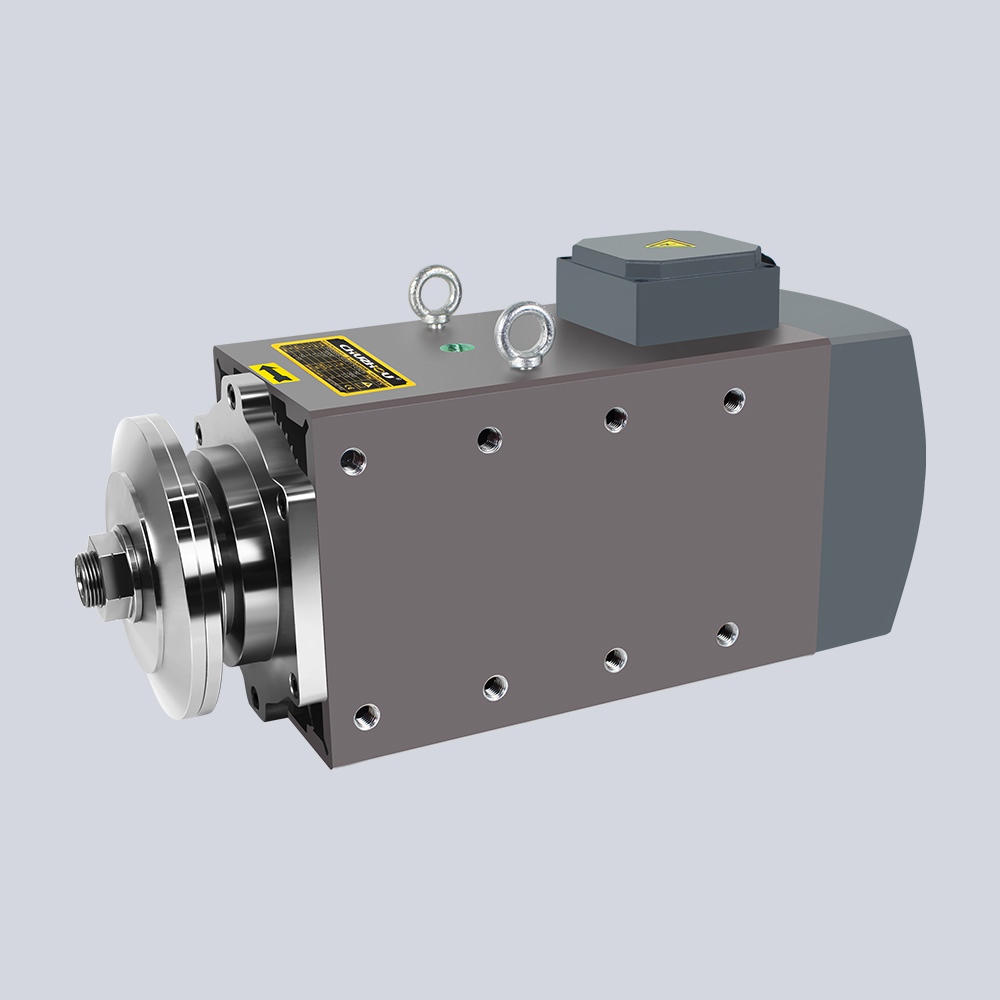

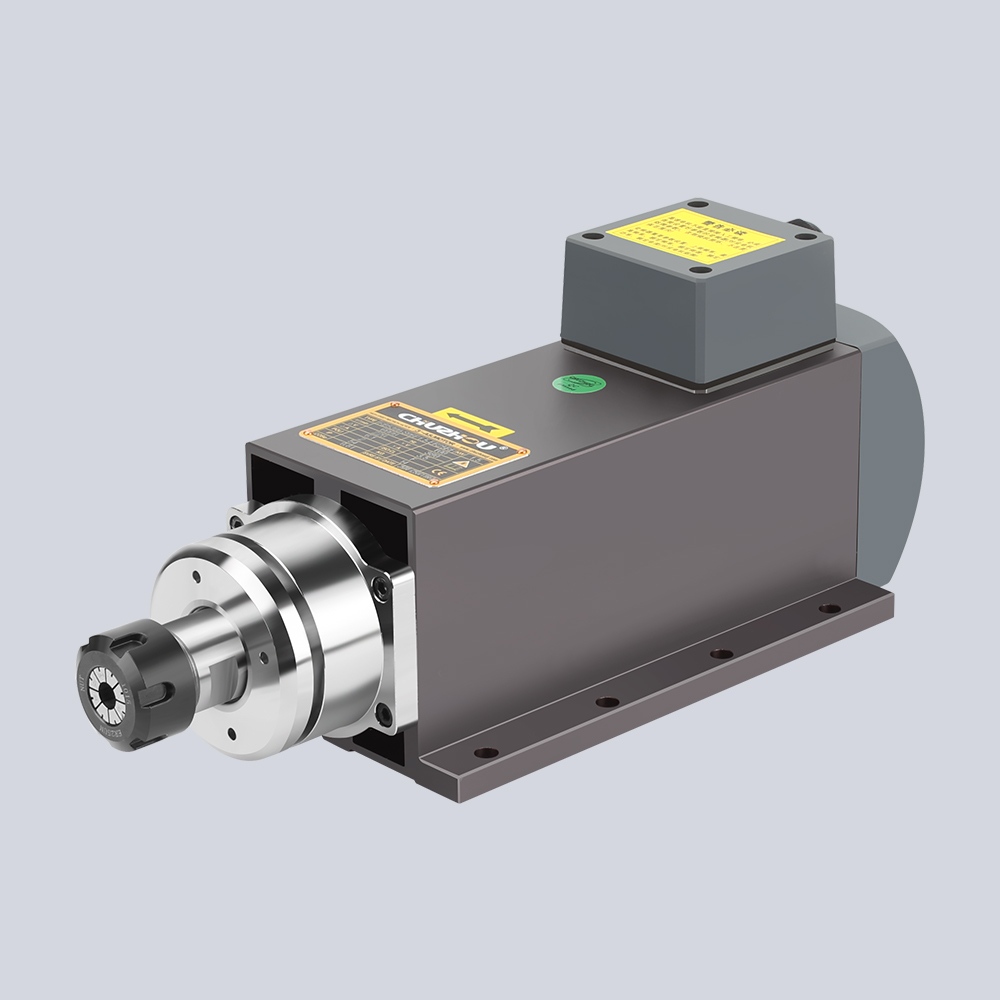

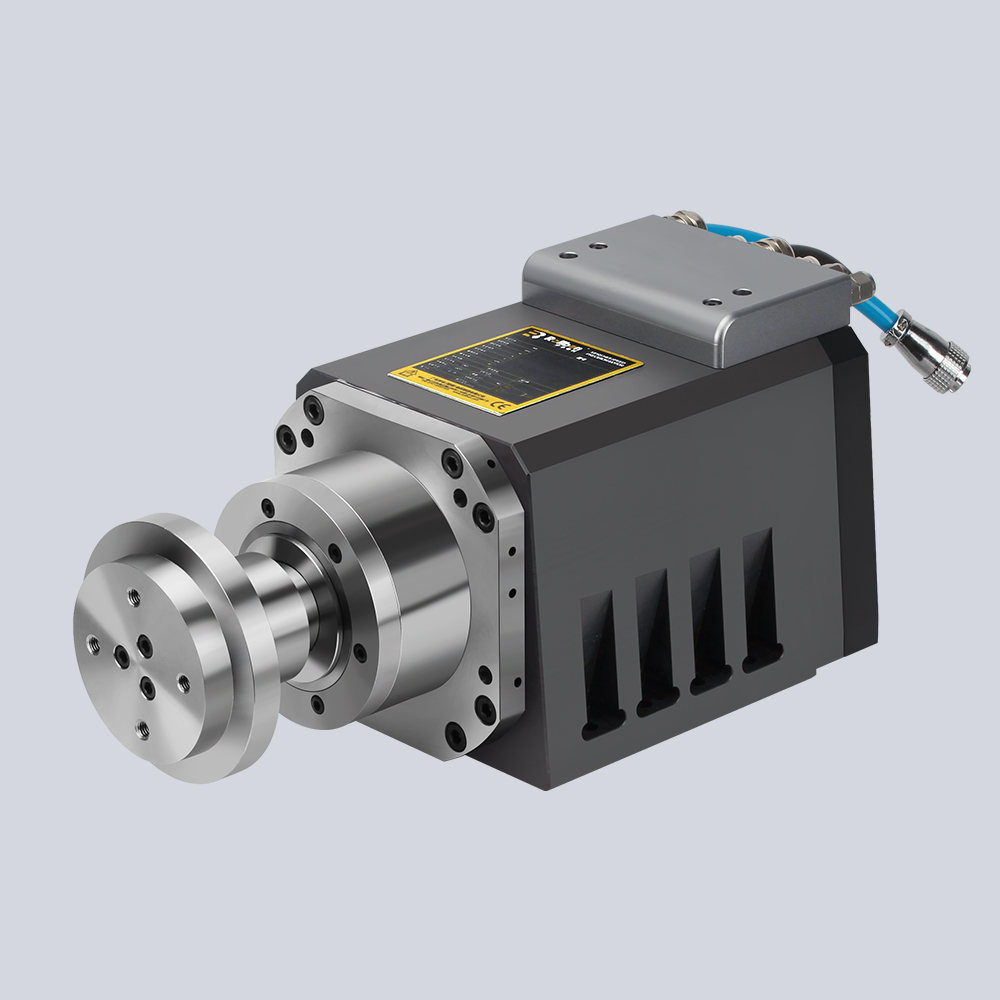

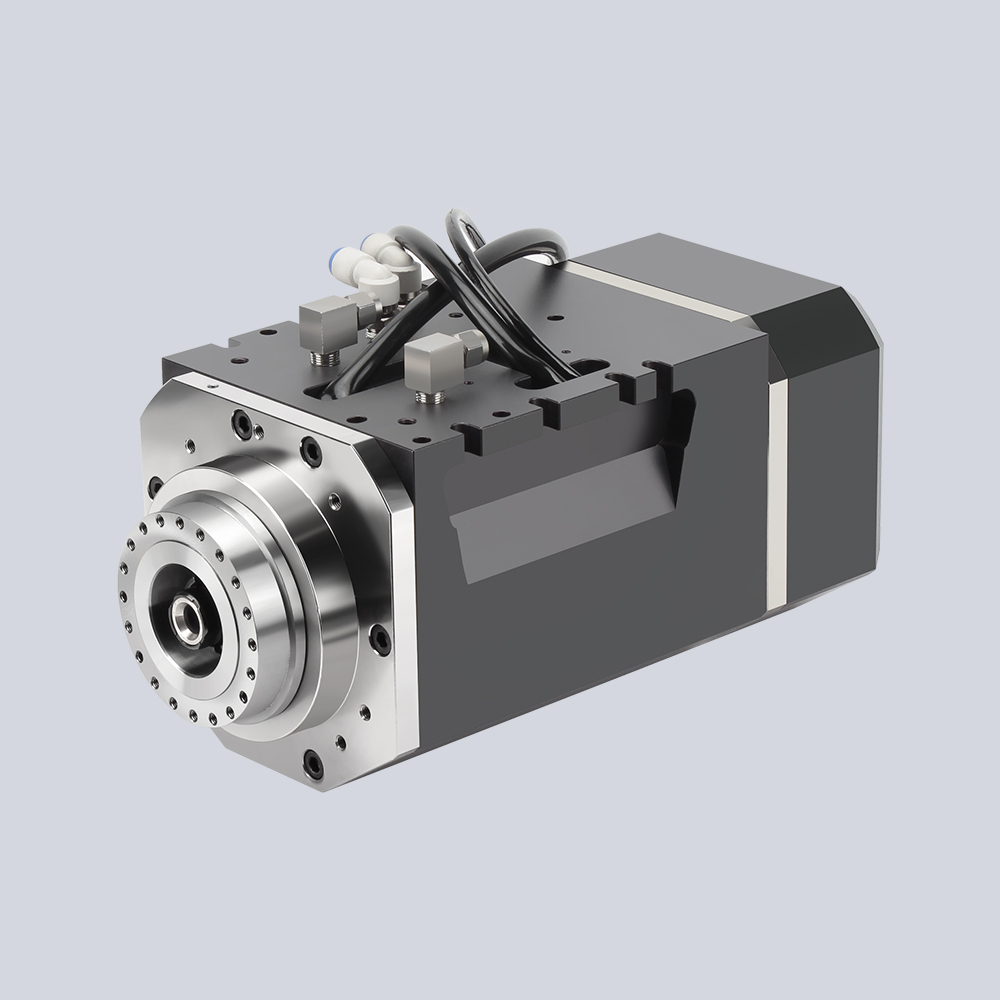

Introduction to High-Speed Precision Spindle Motors

High-speed precision spindle motors are engineered for demanding machining applications, delivering exceptional speed, accuracy, and reliability. Their robust design and advanced technology make them indispensable in industries such as aerospace, automotive, medical devices, and more. Understanding the unique characteristics and operational requirements of these motors is fundamental to their effective installation and operation.

Planning and Preparation

Effective planning lays the foundation for successful installation of high-speed precision spindle motors. Begin by reviewing motor specifications and operational requirements provided by the manufacturer. Evaluate the installation site to ensure it meets environmental and operational criteria, such as vibration levels, space availability, and access for maintenance and service.

Step-by-Step Installation Process

- Motor Mounting and Alignment: Securely mount the spindle motor to a stable, vibration-resistant base or mounting structure. Use precision alignment tools to align the motor shaft with the driven tool or workpiece holder. Proper alignment minimizes mechanical stress, enhances bearing life, and ensures accurate machining performance.

- Electrical and Cooling System Installation: Connect the motor to the appropriate power supply, following electrical wiring diagrams and safety guidelines. Verify voltage, current ratings, and grounding requirements to prevent electrical hazards. Install cooling systems, such as air or liquid cooling, to maintain optimal operating temperatures and protect motor components from overheating.

- Integration with Control Systems: Integrate the spindle motor with existing control systems or programmable logic controllers (PLCs). Configure control parameters, such as speed settings, acceleration/deceleration profiles, and safety interlocks, to align with specific machining requirements. Conduct thorough functional tests to validate control system operation and motor responsiveness.

Commissioning and Testing Procedures

- Startup and Initial Operation: Gradually power up the spindle motor and monitor startup sequences for abnormal noise, vibration, or operational issues. Verify correct rotation direction and smooth ramp-up to operational speeds. Perform initial functional checks and visual inspections to ensure all components are functioning as intended.

- Performance Verification: Conduct comprehensive performance tests to validate motor capabilities under simulated operating conditions. Measure speed accuracy, torque delivery, and thermal performance using calibrated instruments. Compare test results against manufacturer specifications to confirm compliance with design parameters and application requirements.

Safety and Compliance Standards

- Safety Protocols: Prioritize safety throughout the installation process by implementing rigorous safety protocols and procedures. Ensure all personnel adhere to established safety guidelines and wear appropriate PPE when handling and operating equipment. Implement lockout/tagout procedures to prevent accidental startup during maintenance activities.

- Regulatory Compliance: Align motor installation practices with industry standards, regulations, and certifications applicable to high-speed precision spindle motors. Maintain accurate documentation of installation procedures, test results, and compliance certificates for auditing and regulatory purposes.

Ongoing Maintenance and Support

- Establishing Maintenance Regimens: Develop comprehensive maintenance schedules and procedures to sustain motor performance and reliability over time. Include routine inspections, lubrication, and preventive maintenance tasks tailored to the motor’s operational environment and utilization.

- Training and Skill Development: Provide ongoing training for maintenance personnel on motor care best practices, troubleshooting techniques, and emergency response protocols. Access manufacturer support and technical resources to address maintenance challenges and optimize motor performance throughout its operational lifespan.

Conclusion

The successful installation of high-speed precision spindle motors demands meticulous planning, technical proficiency, and adherence to industry standards. By following the systematic approach outlined in this guide—from thorough planning and preparation to precise installation, commissioning, and ongoing maintenance—manufacturers can ensure these critical components operate at peak efficiency. Investing in professional installation not only enhances motor performance and reliability but also supports high-precision machining operations essential for achieving manufacturing excellence

3.5